Lab, industrial and ATEX rotameters

The metal float flowmeters are equipped with a fully welded stainless steel variable cross section. The electronic transmitter with a large LCD display gives instantaneous flow and totalization information for liquid, gas or steam applications.

The metal flowmeters are compatible with opaque or lightly loaded fluids and guarantee safety for the measurement of hazardous or toxic fluids.

Pitot tubes - Flobar

Flobar pressure probes are made of particularly robust pitot tubes designed for easy installation on pipes, ducts or chimneys. Its unique profile increases accuracy and reduces pressure drop. It is a measuring device whose principle has long been recognized for its reliability, accuracy, ease of installation and virtually no maintenance.

Industrial rotameters

These units of measurement, based on the principle of the variable area float, are designed to indicate instantaneous values and monitor the flow in pipes :

- Glass tubes are ideally suited for flow measurement of transparent fluids and gases. They are used, for example, in plant and process engineering.

- Measuring units with magnetic transmission of the vertical position of the float to a dial gauge are recommended for measuring the flow rate of opaque media.

Each unit is customized with a scale specific to the medium to be measured.

Our specialists are here to help you make this choice.

Free and fast quote

+32 (0)4 344 97 34 Request a free and fast quoteThermal mass flowmeters

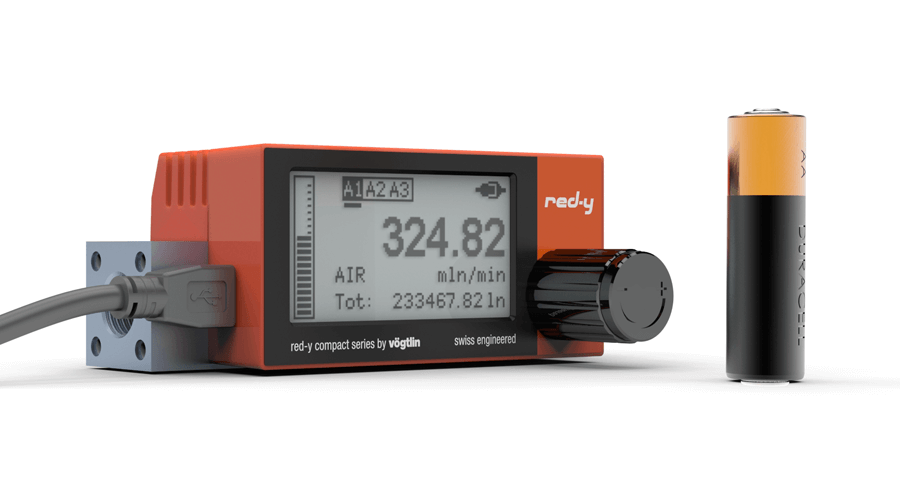

Wherever high measuring dynamics or low pressure losses are required, thermal mass flowmeters are a real alternative to traditional measuring methods.

RED-Y flowmeters offer high accuracy and dynamics:

- Accuracy ± 1% of the final value (depending on application / measuring range)

- Dynamic 1: 100

The new generation of flowmeters offers the user great flexibility: compact design, battery operation, touch screen with backlighting and accurate measurement regardless of the position of the flowmeter.

Orifice plates

Orifice plates or diaphragms are the most commonly used primary elements for differential pressure flow measurement. They allow measurement over a wide range of flow rates and for a wide range of pipe diameters. Inserted in a circular pipe, they create an obstacle, increase the speed of the fluid and generate a pressure difference between upstream and downstream of the restriction. This differential pressure measurement is proportional to the value of the flow rate.

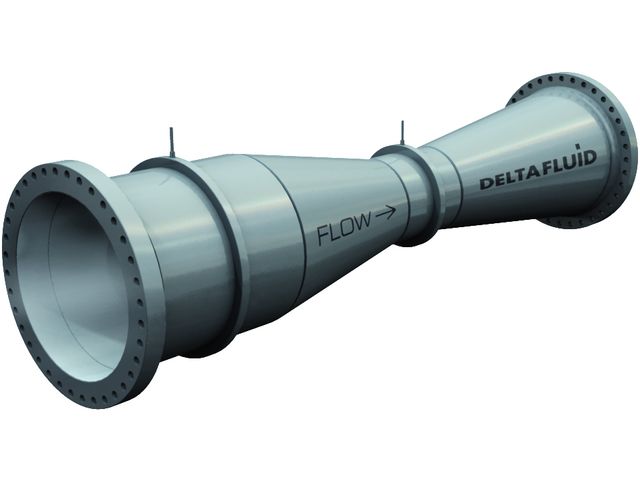

Venturis

The venturi tube has a convergent inlet, a neck and a divergent outlet. It is a differential pressure flowmeter well known to create a low permanent pressure drop, making it suitable for measuring e.g. a low pressure flow. On the other hand, it requires low upstream and downstream straight lengths. There are different types of venturi tubes: the machined venturi made from a solid round for small parts, the welded rolled venturi made from sheet metal for larger parts up to diameter 1200 and the rough foundry venturi for better accuracy up to diameter 800.

Electromagnetic flowmeters

The magneto-inductive flow sensor is specially designed for applications related to the treatment of ground water, drinking water, waste water, polluted water and sludge.

Coriolis Effect Flowmeters

The flowmeters, designed according to the Coriolis principle, allow the measurement of all types of liquids and gases. The multi-parameter equipment allows an exact measurement of mass flow, volume flow, density, temperature and fractionated flow.

Ultrasonic flowmeters

These highly accurate and noise-immune flowmeters are suitable for areas requiring high quality fluid flow measurement.

- Ultrasonic flowmeters in contact with the fluid are designed for the measurement of liquids characterized by good acoustic permeability, regardless of their conductivity, viscosity, temperature, density and pressure.

- Clamp on" ultrasonic flowmeters adapted to your field of application are very easy to install, without pipe separation or flow interruption.