In industry, vacuum technology, like compressed air, can be used as a power source in many applications. In particular, vacuum cups can be used to lift or pull multiple objects.

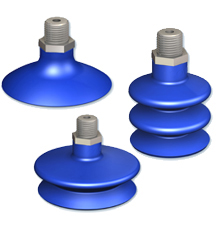

Our product line includes a variety of suction cups in different shapes, sizes and materials, making it possible to find the right suction cup for every application.

We can also provide you with venturi vacuum pumps using the most advanced technologies. They offer a wide suction range, high efficiency, low energy consumption, low weight, small footprint and quiet operation. With many built-in features, they are easier and more cost-effective to install and operate. If you need a larger scale vacuum generator, please visit our vacuum pumps page.

At Elneo, we strive to provide our customers and users with vacuum handling solutions that meet their objectives in terms of profitability, productivity, quality, safety and environmental preservation. Standard products are available from stock and can be delivered within 24 hours.

Our experts are at your side to guide you in the selection of the ideal equipment and accessories for an optimal solution.

For vacuum technology, we have decided to work with Coval. French manufacturer, has been a force of permanent innovation in the field of vacuum automation for 30 years.

Our specialists are here to help you in this choice.

Free and quick quote

+32 (0)498 69 79 25 Ask for a free and fast quoteHow to size a vacuum system ?

1. Select the suction cups and their fixings

Define the appropriate suction cups and fasteners according to the object to be gripped, the necessary movements, the type of object (waterproof or porous), the effort to be provided, the rate, the environment, etc.

Elneo offers a wide range of suction cups, divided into three main groups: standard, specific and generic. Elneo can help you in the choice of the most adapted suction cup to your needs. More explanations on the selection criteria further down this page.

2. Choose the perfect suction source for the suction cup used

Selection of the appropriate vacuum generator according to the suction cups, the type of object (hermetic or porous), the required response times, etc.

Elneo offers a complete range of vacuum pumps using the most advanced technologies.

They offer a wide suction range, optimal efficiency, low-energy consumption, low weight and size, and quiet operation. With many built-in features, they are easier and more cost-effective to install and operate.

3. Auxiliary components

Identify additional components needed to connect, power and control the system. Peripheral components are an essential complement to the vacuum network and ensure a reliable installation.

The risks associated with improper use are increased power consumption and noise and decreased overall efficiency.

Selection criteria for a suction cup

The shape

- Flat suction cups without stop: used for handling flat or slightly rounded, rigid and smooth objects. They are resistant to lateral forces and can be used for vertical handling.

- Flat suction cups with stops: used for handling thin, flexible and deformable objects. They increase the resistance to lateral forces and allow horizontal handling.

- Bellows suction pads: used for handling spherical, cylindrical or ovoid objects. The effect of the technical characteristics increases with the number of bellows. They can be used for gripping objects with height differences, for a ball-and-socket effect, for lifting and for gripping corners or edges.

Calculation of the force of the suction cup

The strength of a suction cup is proportional to its vacuum surface and also depends on its shape, its flexibility, its material and especially on the vacuum level reached inside the suction cup.

Theoretical force

Force = Area of the suction cup (cm2) x Vacuum percentage (%) x 0.01013.

The force indicated in the COVAL suction cup tables is the force of the suction cup measured in practice at 65% vacuum. This figure also includes a safety factor of 2.

Actual Force

As the name implies, this force represents the actual force of the suction cup when in use. In general, it is 50% less than the calculated theoretical force.

This difference is explained by the deformation of the suction cup during handling (which reduces the gripping surface), and by the condition of the surface of the handled object.

The safety factor

All forces are given in the tables for the different ranges of suction cups. These are real values at 65% vacuum, calculated with a safety factor of :

- 2 for horizontal gripping

- 4 for vertical gripping

For applications involving high acceleration, the safety factor will be calculated accordingly.

Diameters

The strength of the suction pad and the available gripping surface of the product depend on this parameter. COVAL offers standard suction cups with diameters ranging from 1 to 600 mm for all its product lines.

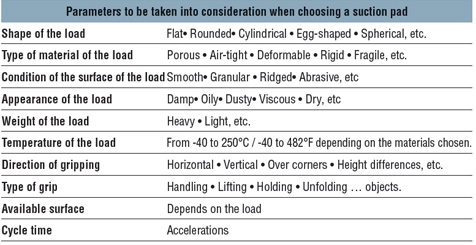

Parameters

Below is the most complete list of parameters to be considered when choosing a suction cup.

The material

To meet the constraints of industrial applications, Elneo has a wide range of standard and specific materials for our suction cups.

This allows us to provide you with the right material for all applications and sectors: food processing, manufacturing, aerospace, industrial, etc.

How to choose a vacuum pump ?

Nature of the object

The function of a vacuum pump is to generate a relative vacuum in a capacity. In vacuum handling, this capacity is generally constituted by the internal volume of the suction cups to be emptied and the volume of the network (piping).

The dimensioning of a vacuum pump will then depend on the nature of the object:

- Airtight objects

Only this capacity is to be taken into account. The choice of the vacuum pump is based on the emptying time corresponding to the application. Since the maximum vacuum level can be reached, it is worthwhile choosing the 90 % vacuum versions (version N).

- Porous objects

In this case, it will not be possible to empty the capacity. Therefore, the leakage rate of the suction cup network must be taken into account. The vacuum pump suitable for this type of handling is therefore a vacuum pump for which the flow rate is significantly higher than the leakage rate in order to create a sufficient pressure drop in the suction cups. A high flow rate is preferable to a high vacuum, a vacuum of 75% (version T), 60% or 50% (version X) for very porous objects like light cardboard, foam, etc.

Calculation of the leakage rate

First, apply a suction cup with a diameter suitable for the object to be grasped. Then, equip a vacuum pump (whose characteristics are known) with a manometer and a vacuum gauge. Supply the vacuum pump with the optimum pressure (e.g. 5 bar). Finally, apply the vacuum cup to the surface to be tested.

There are three possible scenarios:

- The vacuum gauge indicates the maximum vacuum reached for this type of gauge: the object is tight.

- The vacuum gauge does not measure any vacuum: choose a more efficient vacuum pump, because the leakage rate is higher than the maximum flow rate of the vacuum pump.

- The vacuum meter displays a vacuum value, for example -300 mb (30% vacuum), refer to the vacuum pump curve. Read the flow rate corresponding to -300 mb (e.g. 75 NI/ minute).

The leakage rate is 75 Nl/minute for the surface of the suction cup used at -300mb.

From these data, calculate the forces to be applied to handle the object:

- At -300mb the theoretical force of the suction cup is: F = S x 0.3 with:

- S = surface of the suction cup in [cm2].

- F in [DaN]

Elneo is able to provide you with all these suction cups and more, thanks to recognized partners, oriented towards quality and innovation. Our key partner for this product range is Coval.

Our other pneumatic products