Solenoid or solenoid core valves are valves controlled by an electrical signal. Thanks to the principle of on/off opening and closing, they enable the flow of a neutral gas or liquid in a pipe to be controlled with the advantage of a fast response time.

Solenoid valves are differentiated according to 3 main criteria:

- The type of control: direct, assisted or forced control

- Function: Normally Closed or Normally Open

- The number of ports: 2/2 or 3/2 ways

In order to select the correct type of solenoid valve, it is important to know its exact application, the type of fluid, the pressure and temperature range, the control voltage and the nominal flow rate. This technical information is also used to define the body, diaphragm and seal materials; the coil voltage and power; and the valve size.

Servo-assisted valves require a differential pressure (indicated as the minimum value of the operating pressure) between inlet and outlet in order to switch. The majority of solenoid valves operate on this principle. On force-operated valves, this differential pressure is not required. A more powerful solenoid coil assists the diaphragm in its movement (higher acquisition and operating costs). Direct operated valves can be used without differential pressure. Here, the valve is only switched by the magnet. However, this is only cost-effective for small diameters.

Thanks to its choice partners, Elneo offers you a wide range of solenoid valves and services. For each size, between 1/8" and 2", the standard models are available from stock and can be delivered within 24 hours. We also offer customised solenoid valves for specific applications, according to your needs. Our experts are at your side to guide you in selecting the ideal material and accessories required for an optimal solution.

Our specialists are here to help you make this choice.

Free and fast quotation

+32 (0)476 20 69 34 Request a free and fast quotePrinciples of operation

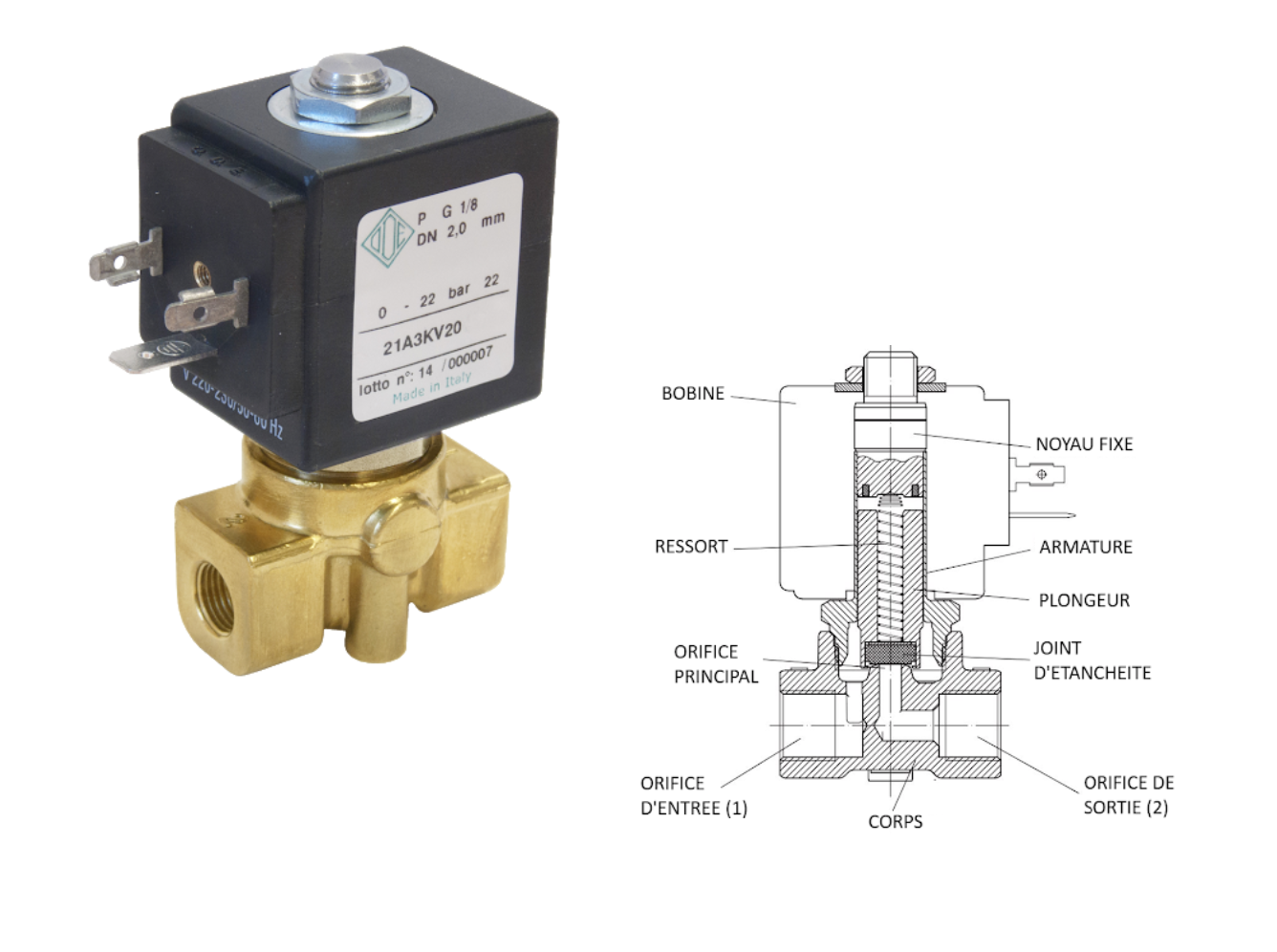

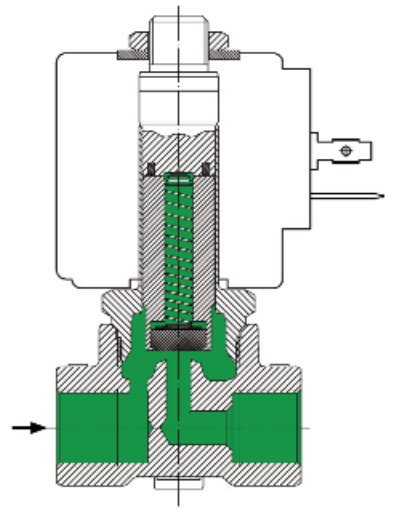

Direct operated solenoid valve:

The plunger is mounted directly on the seal which directly opens and closes the main orifice. When the coil is not energised, the plunger closes the valve under the pressure of the medium and the spring. As soon as the coil is energised, the plunger moves upwards and releases the port for fluid flow.

The advantage of these valves is that they operate without pressure differential. Caution: any increase in pressure requires an increase in the force required to open the valve. If the pressure difference between inlet and outlet is greater than the maximum recommended value, the valve will not open under voltage. This value is defined by the power of the coil.

By design, the main orifice area is reduced in size. These solenoid valves are therefore designed for 1/8" or 1/4" connections.

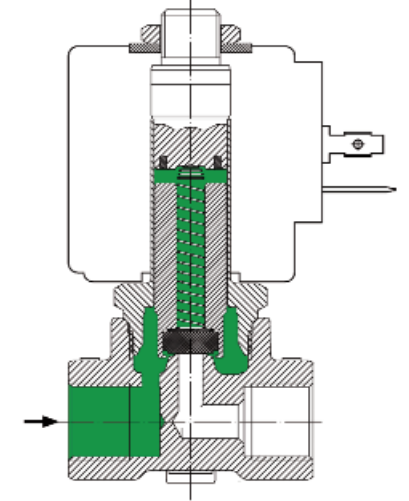

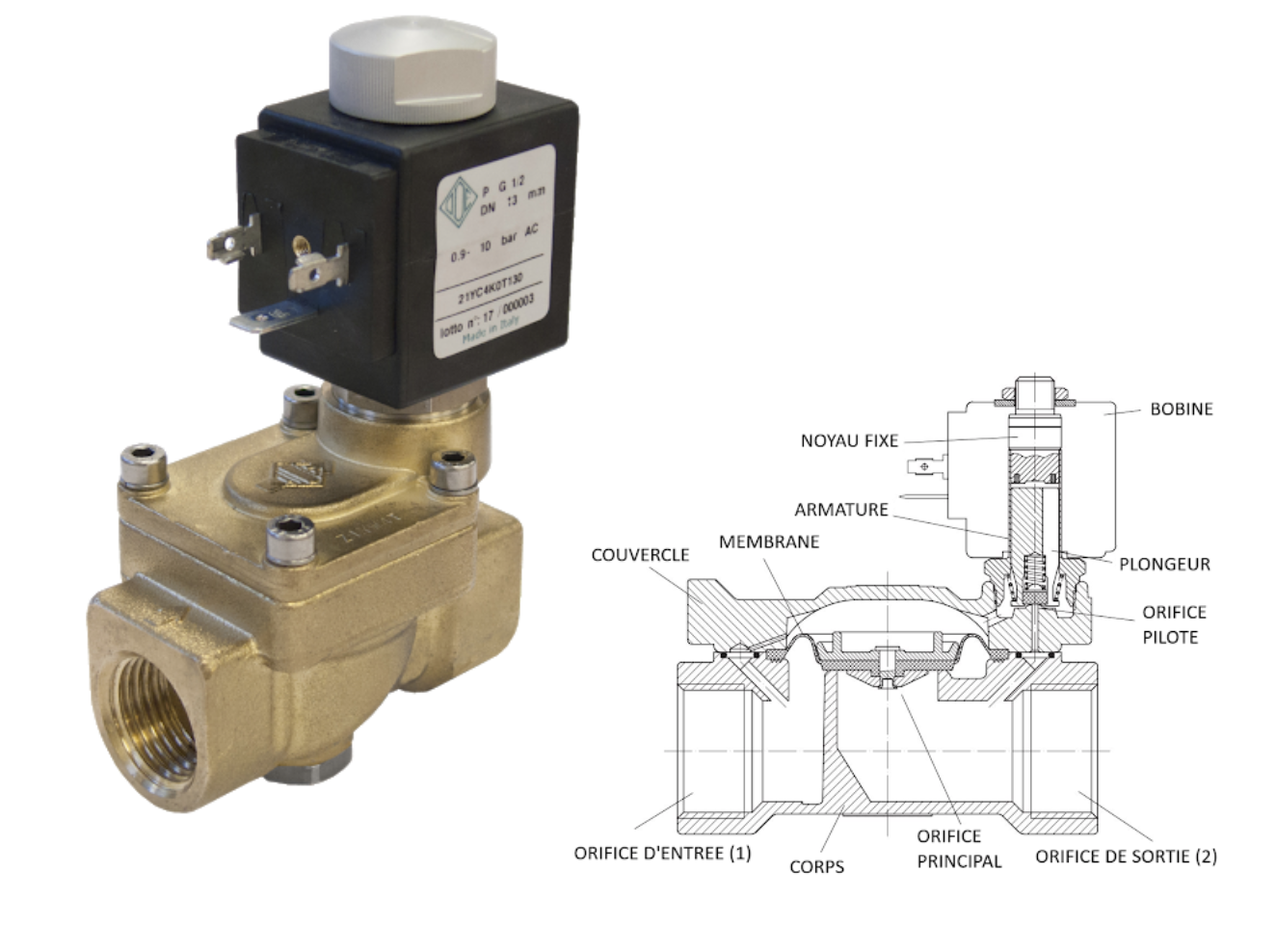

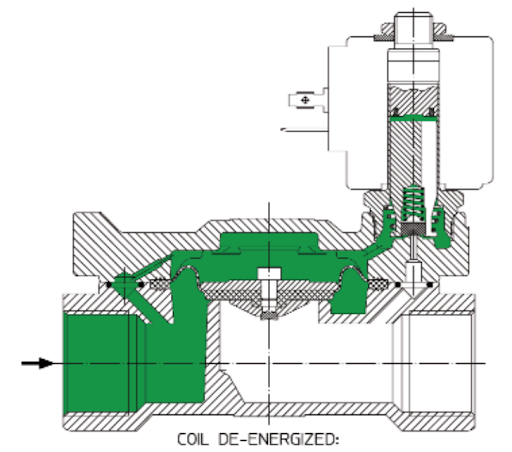

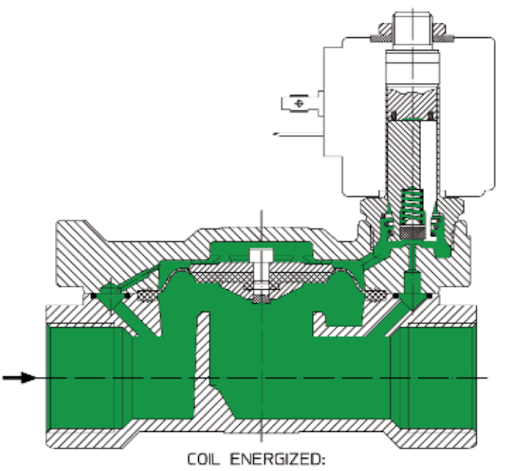

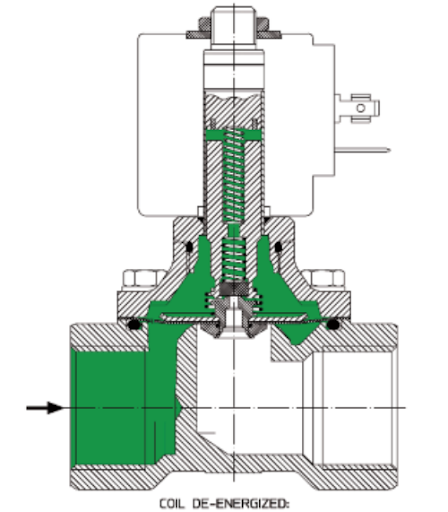

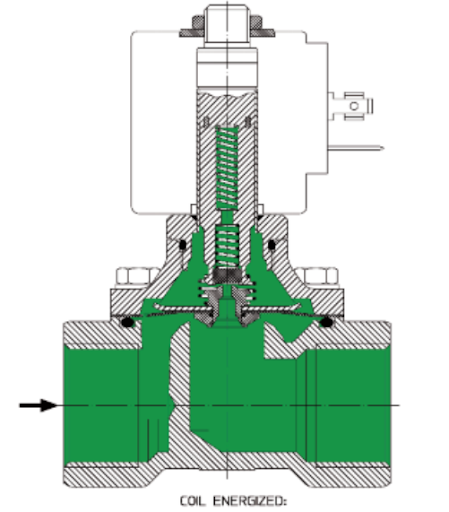

Servo-assisted (or pilot operated) solenoid valve:

The main orifice of the valve opens as a result of a pressure imbalance between the upper and lower surfaces of the diaphragm (membrane). When the coil is not energised, the pressurised medium is distributed throughout the chamber above the diaphragm. Below the diaphragm, only the area outside the main orifice is under pressure. The resultant forces keep the diaphragm closed.

When the coil is energised, the movement of the plunger causes the pilot orifice to open and discharge the chamber above the diaphragm. The pressure imbalance lifts the diaphragm and releases the main orifice.

These valves require a minimum pressure difference between inlet and outlet to ensure proper operation. However, as with direct operated solenoid valves, an excessive pressure difference will result in an increase in the force required to open the pilot orifice.

Application advice:

For correct operation and to avoid rapid wear of the diaphragm, it is not advisable to use the valve in free outlet, without area restriction, if the inlet pressure is higher than 1 bar when the valve is open.

In addition, special attention must be paid to the problem of water hammer when designing the circuit. This physical phenomenon can cause the diaphragm to tear or abnormal wear of the components.

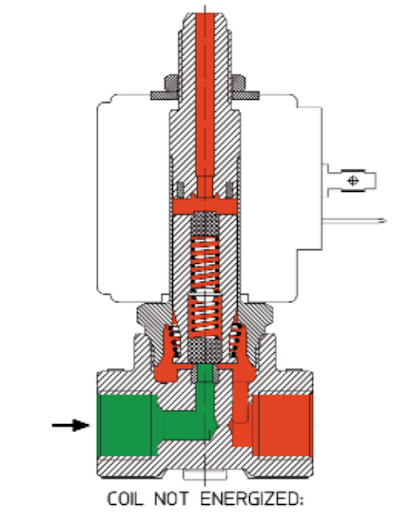

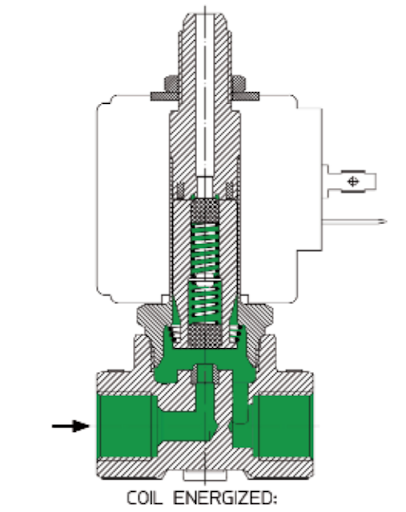

Forcibly operated solenoid valve:

The main orifice of the valve opens due to a pressure imbalance between the upper and lower surfaces of the diaphragm (diaphragm) in conjunction with the direct action of the plunger which is attached to the diaphragm. The operation is essentially the same as that of pilot operated solenoid valves at the diaphragm, except that it remains assured even with small pressure differences between inlet and outlet due to the direct action of the plunger on the diaphragm.

When the coil is not energised, the pressurised fluid fills the chamber above the diaphragm, while below the diaphragm pressure is applied only in the area outside the main orifice. The resultant forces push the diaphragm to close the main orifice. When the coil is energised, the plunger releases a port on the diaphragm and discharges the chamber above the diaphragm. At the same time, the plunger exerts a direct force on the diaphragm, facilitating its opening. The sum of this force and the unbalanced pressure on the diaphragm lifts the diaphragm and opens the main orifice.

The advantage of these valves is that they operate without pressure differential. Caution: any increase in pressure requires an increase in the force required to open the valve. If the pressure difference between inlet and outlet is greater than the maximum recommended value, the valve will not open under voltage. This value is defined by the power of the coil.

Application advice:

For correct operation and to avoid rapid wear of the diaphragm, it is not advisable to use the valve in free outlet, without restriction of cross-section, if the inlet pressure is higher than 1 bar when the valve is open.

In addition, special attention must be paid to the problem of water hammer when designing the circuit. This physical phenomenon can cause the diaphragm to tear or abnormal wear of the components.

Direct operated 3/2-way solenoid valve:

Normally closed 3-way solenoid valves have one inlet (1), one outlet (2) and one exhaust (3). The plunger, on which two seals are mounted, simultaneously opens or closes the main orifice of the solenoid valve and opens or closes the exhaust orifice.

When the coil is not energized, the plunger blocks the main orifice, preventing fluid flow from the inlet to the outlet, while the outlet is exhausted. When the coil is energised, the plunger moves upwards, opening the main orifice and closing the exhaust port, allowing fluid to flow from the inlet to the outlet by plugging the exhaust.

In contrast to other models, on 3/2-way valves, the medium must flow through the main orifice from the bottom side to the top side.

Caution: Any increase in pressure requires an increase in the force required to keep the valve closed. If the pressure difference between inlet and outlet is higher than the maximum recommended value, the valve will open by itself, without tension. This value is defined by the spring return force.

Here are the models encountered in the industry that are part of our catalogue: brass, stainless steel, gas, oil, oxygen, ATEX, ...

Elneo is able to supply all these solenoid valves with many variants, thanks to recognised partners who are oriented towards quality and innovation. Our Key Partner for this product range is ODE.

Our other pneumatic products