What is the purpose of condensate treatment?

Although compressed air is one of the least polluting energies available on an industrial scale, its production nevertheless generates "liquid pollution" that must be channeled, evacuated and reprocessed.

This liquid pollution is composed of water (from the condensation of the water vapor contained in the ambient air following compression) to which is added the oil generated by the compression technology as well as the particles sucked in. This extremely polluting, corrosive and abrasive mixture can cause irreversible damage to your compressed air systems.

How can we help you?

Timer drains

The role of timer drains is to efficiently and economically drain condensate at the various collection points:

- At the compressor separator

- Under the buffer tank

- To air or water final heat exchangers

- To refrigerated dryers

- To filters and low points in the network

Level sensed drains

Level sensed drains have exactly the same role as their timed cousins but work differently: while timed traps drain condensate at a fixed time interval, capacitive traps are able to measure the accumulation of condensate so that they are only discharged at the right time. This saves energy because the leakage rate is minimized.

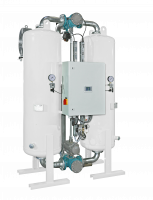

Water/oil separators

- The condensate separator is the simple, inexpensive and effective solution to reduce the oil concentration in condensate.

- The recovered water can represent up to 99% of volume and can be safely discharged to the sewer.

- The small amount of concentrated oil is then disposed of economically and legally.